The Polyphase Induction Motor is an engine whose stator contains various windings. They are more prominent than one torque or one kilowatt. The National Electrical Manufacturers Association (NEMA) has indicated the engines as per the different Class, which are talked about beneath in detail. There are different utilizations of Polyphase injury rotor acceptance engines, Polyphase confine enlistment engines. They are as per the following:

Utilizations of Polyphase Wound Rotor Induction Motors

Wound rotor engines are reasonable for loads requiring high beginning force and where a lower beginning current is required.

The Wound rotor enlistment engines are likewise utilized for loads having high dormancy, which brings about higher vitality misfortunes.

Utilized for the heaps which require a slow development of force.

Utilized for the heaps that require speed control.

The injury rotor enlistment engines are utilized in transports, cranes, siphons, lifts and blowers.

The greatest force is over 200 percent of the full burden esteem while the full burden slip might be as low as 3 percent. The proficiency is around 90 %.

Utilizations of Polyphase Cage Rotor Induction Motors

Numerous polyphase confine enlistment engines are accessible in the market to fulfill the need of the few mechanical applications and different beginning and running condition necessity. They are ordered by the Class.

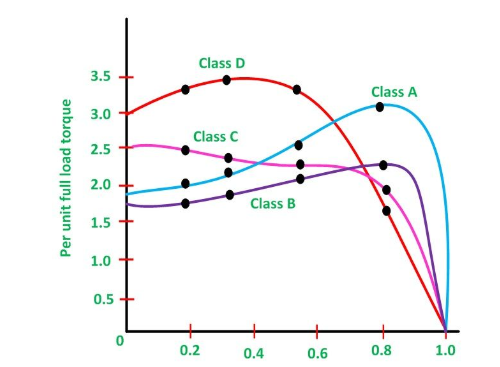

The speed force qualities of Cage Induction Motor of different Classes are demonstrated as follows.

Class A Motors

Class An engines have typical beginning force, high beginning current and low working slip (0.005-0.015). The structure has low opposition single enclosure rotor. The productivity of the engine is high at full burden. Uses of Class An engines are fans, blowers, divergent siphons, and so forth.

Class B Motors

Class B engines have ordinary beginning force, low beginning current and low beginning current and low working slip. The engine is structured, in such an approach to withstand the high spillage reactance, therefore, the beginning current is diminished. The beginning force is kept up by utilization of a twofold enclosure or profound bar rotor.

The Class B engines are most regularly utilized engine and utilized for full voltage beginning. The applications and the beginning force are same as that of Class An engines.

Class C Motors

The class C engines have high beginning force and low beginning current. Such engines are of the twofold pen and profound bar and has higher rotor opposition. The heaps are blowers, transports, responding siphons, smashers, and so forth.

Class D Motors

Class D engines have the most elevated beginning force when contrasted with the various class of engines. The bars of the rotor confine are comprised of metal. These sorts of engines have low beginning current and high working slip. The estimation of full burden working slip changes between 8 to 15%. In this way, the productivity of the engine is low.

These engines are reasonable for driving discontinuous burdens which require visit speeding up and high loads. For instance – punch presses, pieces of machinery and kick the bucket stepping machines. At the point when the engine is driving the high effect loads, it is coupled to a flywheel to give active vitality.

No comments:

Post a Comment

If you have any Doubt, Please let me know